porthole

Retired

This is my initial post from the other thread on mounting one of these little hydraulic hoists.

First 4 of 6 holes

From these two pics you can see where the bed is collapsing.

So, this thread got me wondering again.

I have a nice winch hanging from the rafters in my garage. Works great - on a truck that can actually fit in the garage.

Some angle iron and pipe. This spans five rafters. The winch slides left and right for alignment.

https://heartlandowners.org/showthr...re-heavy?highlight=pullrite+hitches+are+heavy

Hanging from the king pin. Have done that - once. Way to difficult to get lined back up to drop in the bed. And at near 300 hundred pounds, it has to be lined up perfect, fore-aft, side to side and level.

And if you are not careful, you can easily have the lowered tailgate hit the forward baggage door on the trailer.

I bought a used engine hoist off Craigslist, $45. That works pretty good and has just enough reach to pick the hitch with the tail gate down. But it is much more stable moving the hoist in with the tailgate up. The hoist has enough lift to almost clear the tailgate up.

The engine hoist has just enough drop to allow the hitch to land on a Costco dolly. From there the hitch gets rolled under the Cyclone.

The problems with any small jib-crane are capacity (where you need it, eg extension), reach, drop, rotational ability under load and vertical lift / drop

Plan C has always been one of the truck mounted cranes.

Parking lot sale at HF this week.

This for $69

http://www.harborfreight.com/12-ton-capacity-pickup-truck-crane-60732-9889.html

This for $59

http://www.harborfreight.com/2500-l...winch-with-wireless-remote-control-61297.html

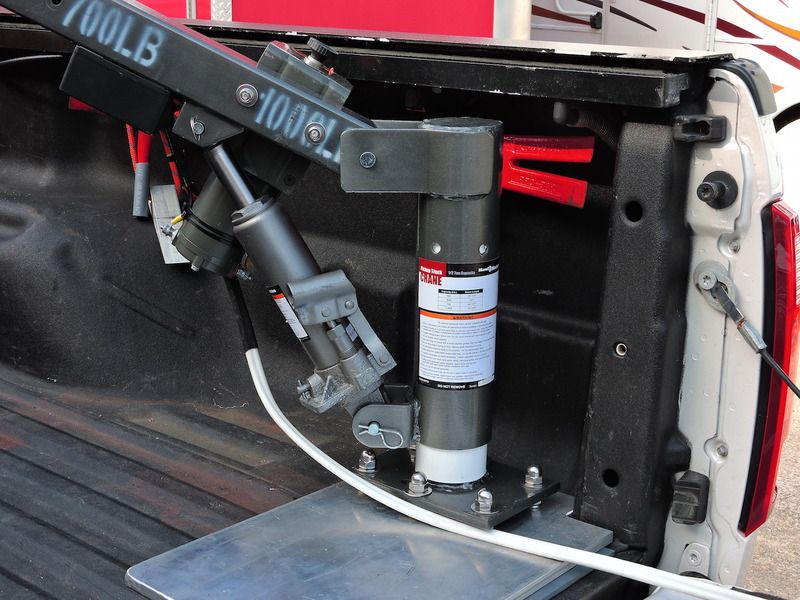

I had some 3/8" aluminum plate, made backing plates for the top and underneath of the bed.

I mounted the electric winch to the side of the jib.

Mounted the fairlead to the end of the jib.

This will do until I can come up with better rollers and direction change wheels.

Sandwiched the two 3/8" plates with 1/2" bolts to the right rear corner of the bed. Used bolts long enough to allow permanent bolting of the plates, but with enough exposed thread for the crane's base to drop over the bolts.

This way I can remove-install the crane as needed.

Reality. I have just enough reach with the jib extended all the way, almost. With my cable lift not enough reach, so I still have to use the supplied hook.

The little crane worked OK for what I wanted, it lifted the hitch. The winch also did it's part in lifting.

Rotating was a different story. Lot of friction with 300 pounds hanging on the end of a 53" arm.

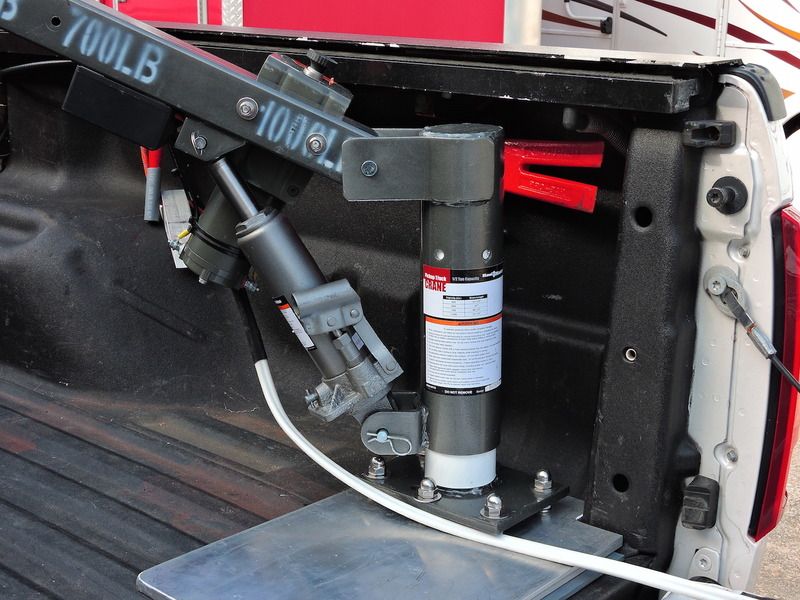

After rotating just a bit the the truck's bed showed it was not strong enough and the hitch pulled the floor up in the corner just enough to allow the hitch to rest on the bed. Nothing a persuader can't fix.

Back to Plan B. Have to assemble my not portable engine hoist to get the now not mounted hitch out of the bed.

I think this can still work though.

Later today I'll be heading over to our local metal goods supplier to see if I can get an 18" square piece of aluminum, 3/8" to 1/2" thick.

18" will give me enough coverage to pick up what little structural steel is under the bed.

First 4 of 6 holes

From these two pics you can see where the bed is collapsing.

Last edited: