wingfoot

Well-known member

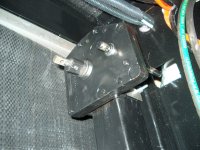

After reading a post on supporting your landing gear motor, I found that mine is VERY, VERY loose. You can actually wiggle it around...This can't be right . Plus, I was also going to lube the gears...It's a sealed unit and I can't see how, as others have mention, lube it..Mine is a Venture OE system and I have always been suspect that the motor was straining/slow. I know others have added another motor but if that is/was necessary, why didn't Heartland solve this potential problem during manufacturing the trailer..I suspect $$$$...sad!

. Plus, I was also going to lube the gears...It's a sealed unit and I can't see how, as others have mention, lube it..Mine is a Venture OE system and I have always been suspect that the motor was straining/slow. I know others have added another motor but if that is/was necessary, why didn't Heartland solve this potential problem during manufacturing the trailer..I suspect $$$$...sad!

Larry

Larry