porthole

Retired

My ramp was shipped by truck freight. Driver showed up as scheduled and then we both looked at each other. In the crate the ramp was billed at 350 pounds. The crate was taller then the trucks door - problem.

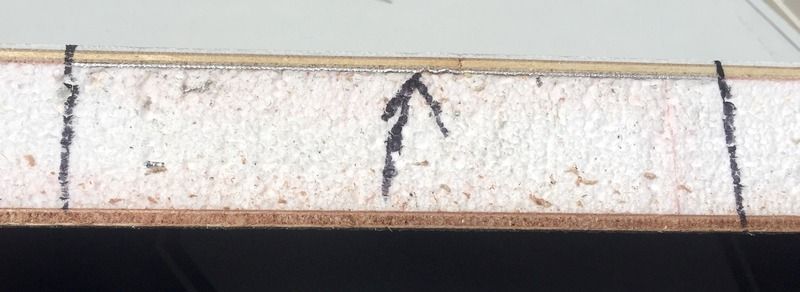

We uncrated the ramp in the trailer and laid it flat on the short side and the two of us were able to easily slide it out of the trailer onto the back of my truck, using the foam from the packing.

The peanut gallery was requested to go inside to not see what we were doing, but instead chose to get video evidence in case she needed to prove to insurance that a door really did fall on me

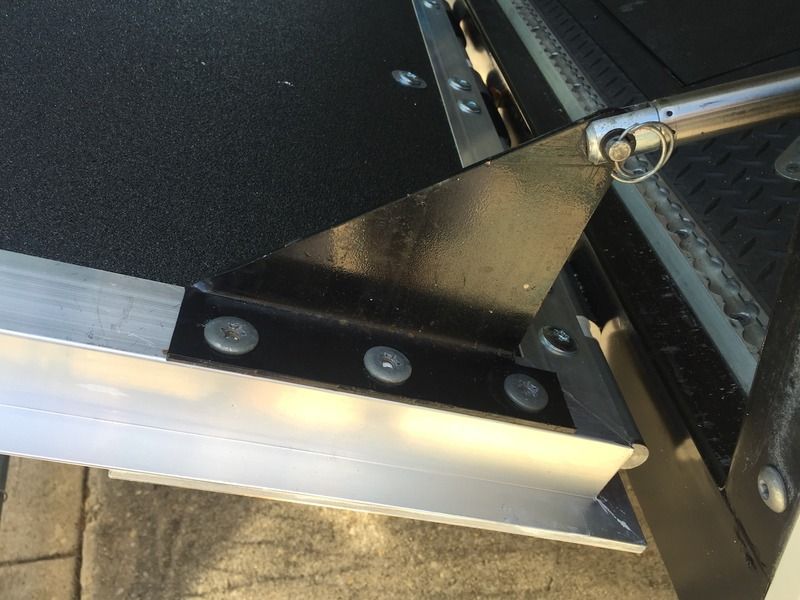

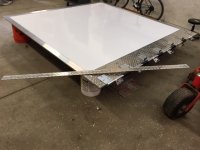

Deb and I were able to maneuver the ramp fairly easily from the back of my truck to the ground then flip onto my garden trailer to move it around as needed.

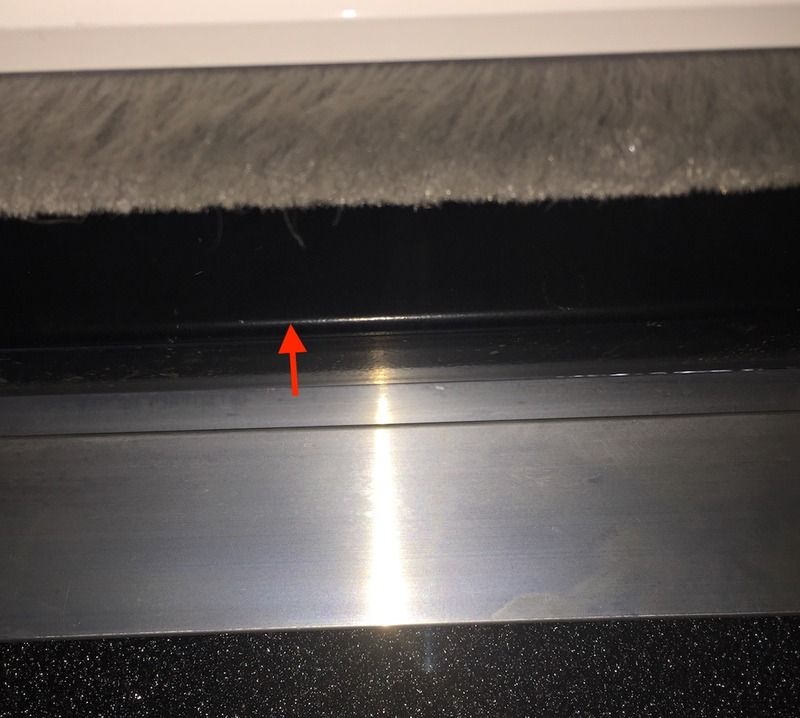

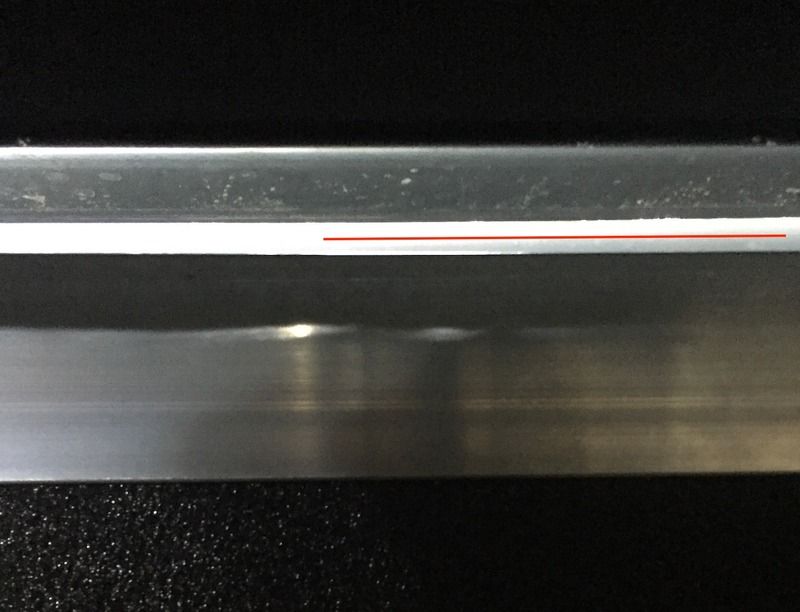

And as it turned out, the garden trailer was just about the right height to aid with the install, with perfect alignment achieved with the LevelUp.

The Conway driver went above what is expected and received a tip suitable for him and his wife to go to a nice restaurant.

We uncrated the ramp in the trailer and laid it flat on the short side and the two of us were able to easily slide it out of the trailer onto the back of my truck, using the foam from the packing.

The peanut gallery was requested to go inside to not see what we were doing, but instead chose to get video evidence in case she needed to prove to insurance that a door really did fall on me

Deb and I were able to maneuver the ramp fairly easily from the back of my truck to the ground then flip onto my garden trailer to move it around as needed.

And as it turned out, the garden trailer was just about the right height to aid with the install, with perfect alignment achieved with the LevelUp.

The Conway driver went above what is expected and received a tip suitable for him and his wife to go to a nice restaurant.

Last edited: