Dr.Lightning

Member

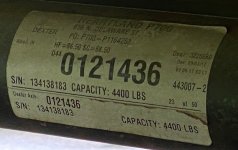

So I have this feeling that my trailer brakes aren't as strong 12 months after I first bought this used Heartland Pioneer, at which time I had the brakes checked by my own mechanic. I could be mistaken about this feeling. They never locked up on asphalt, but I have this feeling for the jerk behind me when I manually engage the trailer brakes only, and I have a feeling that this jerk isn't the same. All trailer brake settings are unchanged.

I went through a whole bunch of checking using an oscilloscope, looking at the the brake signal and the drop across the ground reference at various places (battery, 7-pin trailer plug, travel trailer junction box, wire junctions right at the front right wheel of two axles). Note that I have a PhD in Electrical Engineering and I have done race car data acquisition electronics hardware/software/firmware design for 30 years. So I really should know what I'm doing, unless I'm going insane.

SANITY CHECK: I have a 2015 RAM 1500 with oem brake controller. This thing produces a maximum 75% duty cycle square wave for braking. The peak-to-peak magnitude of that signal is 15.6 volts measured right at the wire junctions next to the front right trailer wheel (two axles). Ignoring the 0.2V excess, this is the exact same peak-to-peak magnitude of 15.4 volts that I measure everywhere else. So while there is a variation in ground of as much as 2.2V, that REALLY DOES NOT MATTER if the two wires right at the wheel are measuring 15.6V. THIS IS MY ONLY SANITY CHECK QUESTION RIGHT NOW, NOTHING ELSE. So, am I correct that as long as the peak-to-peak magnitude of the square wave right at the wheel is 15.6V, then nothing else matters relative to sufficient or insufficient ground wires or brake power wires. Right?

See, if the above is true, then there simply cannot be anything wrong with my wiring or brake controller. 15.6V right at the brakes themselves (at least a few inches away at the wire junctions next to the wheel), means that the brakes are getting the full voltage range possible. Only secondary questions remain, like why did I measure 15.6V p-p at the brake, while all other measurements were 15.4V p-p, with different ground references while signal was at the TT junction box (resolved below). I call this "secondary" because 15.6V or 15.4V, Tomato/Tomaato, shouldn't make any difference. Also, why does the brake controller never issue more than a 75% duty cycle? That's just what this 2015 RAM 1500 oem brake controller does. Furthermore, changing the setting from "Light Electric" to "Heavy Electric" actually goes the opposite way from expected on many forums I visited -- the duty cycle goes down to 61%, thus providing even less net braking. (It seems "Heavy" doesn't mean, "I got me a heavier trailer so I need more braking power". Instead perhaps it means, "the brakes themselves are stronger and so I don't need as much braking signal to get the braking I need.")

So, I ask once more. Within the constraint that the oem brake controller won't send out more than a 75% duty cycle signal, as long as I have full voltage right there at the two wires going into the brakes, then the signal going in to the brakes is the best it's going to ever be with this controller.

Finally about this "15.6V" thing. At the same time as the signal going to the brakes themselves is 15.6V p-p, the battery is at 14.5V. Meanwhile, the negative excursion of the square wave is between -1.62V and -2.2V, depending on which point I'm using as a ground reference. So at this point it's obvious to me that this 2015 RAM 1500 oem controller has a negative power supply inside of it that's generating at least an extra -1V on the ground side, if not -2V. Perhaps it does this to compensate for anticipated poor trailer brake wiring, perhaps poor trailer brake ground wiring. So this darned negative voltage I'm seeing is perhaps not due at all to voltage drop in my wiring, but because the controller is generating it on purpose. In addition, on my last check, with ground vs signal both measured at the truck connector, that 15.4V p-p was actually fluttering a little on the scope numerical analysis result, between 15.4V and 15.6V. So simple fluttering of this value answers the 15.4V vs 15.6V question. Maybe it is actually very close to 15.5V, but the numerical analysis display rounds to 0.2V and thus flutters between 15.4V and 15.6V as the 15.5V varies ever so slightly. I've known this effect extremely well since I think 1992, including watching it on live video behind the astronauts on the space shuttle (or station) way back then. So I don't think that's in fact any measurement difference at all. This leaves me with my original question. If I'm seeing 15+ V right at the brakes, then I do NOT have a brake wiring issue, in the trailer or the truck, that needs to be fixed. Right? Or am I going insane?

I went through a whole bunch of checking using an oscilloscope, looking at the the brake signal and the drop across the ground reference at various places (battery, 7-pin trailer plug, travel trailer junction box, wire junctions right at the front right wheel of two axles). Note that I have a PhD in Electrical Engineering and I have done race car data acquisition electronics hardware/software/firmware design for 30 years. So I really should know what I'm doing, unless I'm going insane.

SANITY CHECK: I have a 2015 RAM 1500 with oem brake controller. This thing produces a maximum 75% duty cycle square wave for braking. The peak-to-peak magnitude of that signal is 15.6 volts measured right at the wire junctions next to the front right trailer wheel (two axles). Ignoring the 0.2V excess, this is the exact same peak-to-peak magnitude of 15.4 volts that I measure everywhere else. So while there is a variation in ground of as much as 2.2V, that REALLY DOES NOT MATTER if the two wires right at the wheel are measuring 15.6V. THIS IS MY ONLY SANITY CHECK QUESTION RIGHT NOW, NOTHING ELSE. So, am I correct that as long as the peak-to-peak magnitude of the square wave right at the wheel is 15.6V, then nothing else matters relative to sufficient or insufficient ground wires or brake power wires. Right?

See, if the above is true, then there simply cannot be anything wrong with my wiring or brake controller. 15.6V right at the brakes themselves (at least a few inches away at the wire junctions next to the wheel), means that the brakes are getting the full voltage range possible. Only secondary questions remain, like why did I measure 15.6V p-p at the brake, while all other measurements were 15.4V p-p, with different ground references while signal was at the TT junction box (resolved below). I call this "secondary" because 15.6V or 15.4V, Tomato/Tomaato, shouldn't make any difference. Also, why does the brake controller never issue more than a 75% duty cycle? That's just what this 2015 RAM 1500 oem brake controller does. Furthermore, changing the setting from "Light Electric" to "Heavy Electric" actually goes the opposite way from expected on many forums I visited -- the duty cycle goes down to 61%, thus providing even less net braking. (It seems "Heavy" doesn't mean, "I got me a heavier trailer so I need more braking power". Instead perhaps it means, "the brakes themselves are stronger and so I don't need as much braking signal to get the braking I need.")

So, I ask once more. Within the constraint that the oem brake controller won't send out more than a 75% duty cycle signal, as long as I have full voltage right there at the two wires going into the brakes, then the signal going in to the brakes is the best it's going to ever be with this controller.

Finally about this "15.6V" thing. At the same time as the signal going to the brakes themselves is 15.6V p-p, the battery is at 14.5V. Meanwhile, the negative excursion of the square wave is between -1.62V and -2.2V, depending on which point I'm using as a ground reference. So at this point it's obvious to me that this 2015 RAM 1500 oem controller has a negative power supply inside of it that's generating at least an extra -1V on the ground side, if not -2V. Perhaps it does this to compensate for anticipated poor trailer brake wiring, perhaps poor trailer brake ground wiring. So this darned negative voltage I'm seeing is perhaps not due at all to voltage drop in my wiring, but because the controller is generating it on purpose. In addition, on my last check, with ground vs signal both measured at the truck connector, that 15.4V p-p was actually fluttering a little on the scope numerical analysis result, between 15.4V and 15.6V. So simple fluttering of this value answers the 15.4V vs 15.6V question. Maybe it is actually very close to 15.5V, but the numerical analysis display rounds to 0.2V and thus flutters between 15.4V and 15.6V as the 15.5V varies ever so slightly. I've known this effect extremely well since I think 1992, including watching it on live video behind the astronauts on the space shuttle (or station) way back then. So I don't think that's in fact any measurement difference at all. This leaves me with my original question. If I'm seeing 15+ V right at the brakes, then I do NOT have a brake wiring issue, in the trailer or the truck, that needs to be fixed. Right? Or am I going insane?

Last edited: