Hello community!

My concrete driveway has about a 6 degree slope and I'm unable to level my coach (front to back) when in the driveway. I want to make some tapered blocks that can be placed under the front jack pads to give me (and my RVing guests) the ability to level out.

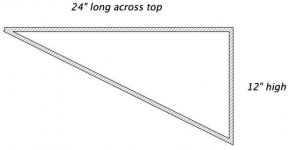

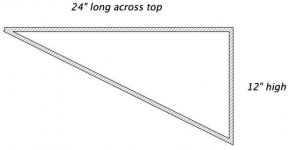

Below is a crude drawing of what I'm thinking of. Note, IT IS NOT drawn to scale. Just a quick and dirty sketch to get the conversation rolling.

Things I need to determine:

My concrete driveway has about a 6 degree slope and I'm unable to level my coach (front to back) when in the driveway. I want to make some tapered blocks that can be placed under the front jack pads to give me (and my RVing guests) the ability to level out.

Below is a crude drawing of what I'm thinking of. Note, IT IS NOT drawn to scale. Just a quick and dirty sketch to get the conversation rolling.

Things I need to determine:

- What is the tallest I should make the blocks? I'm using 12" as a discussion starter, but I'm thinking that may be too high. I guess I'd need to know, when hitched and with front jacks all the way up, on most Heartland 5th wheel coaches, what is the distance from the bottom of the jack pad to the ground. Then maybe use the shortest distance as my number for block height at the front edge.

- What is an ideal width of the blocks? I'm thinking twice the with of the largest jack foot used on our coaches.

- What is the ideal length (flat across the top) of the blocks? I'm thinking 18" to 24". I want to make sure it is very stable as there will be great pressure on the coach to roll forward. Don't want to roll a block! Of course, wheels need to be chocked before unhitching and remain chocked in this driveway.

- What material should I use for block construction? I called a Heartland friend and he suggests that I alternate treated plywood and treated lumber, all stood on edge. Then connect them with all-thread, thereby ending up with a laminated sandwich of treated lumber being used at its strongest orientation. What would you do? Bear in mind, I'm trying to support up to 2500 pounds on each block (about 50 pounds per square inch of contacted surface area) in a worse case loading scenario.

- At the back (left end of drawing) of the block, I don't really want it tapered to zero in a point sort of fashion, so I'd likely square that point (tip) off at some point. Am I "on track" with squaring the back end off?