jonell.dan

Member

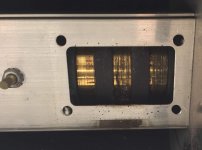

We had no power in our 5th wheel last week and after a couple of days of numerous tests we found our problem. We had a loose wire under the metal panel on the inside of our power cord reel. The red wire had melted almost the entire way through. In fact when we removed the nut holding the wire to the stem the wire broke apart. Fortunately we didn’t have an electrical fire. See attached photos.

Our question: Has anyone ordered a package to replace just the electrical connectors on the power cord reel? The reel still works fine and it would be nice to not have to pay $500 for a new reel plus what looks like a very tedious uninstall and reinstall. We did read numerous posts on the Heartland Forum relating to power reel issues and didn’t see an answer to our question.

For those interested in the electrical tests that were performed before we discovered the melted wire, here is the list:

- There was no power in the rig, so we asked our neighbors if they had power, and they all did.

- We checked for any blown circuits and there was none.

- We then used a multimeter to test the power at our outdoor pedestal and both hot lines registered 120 volts.

- We checked the power in our circuit panel on our double 50 amp breaker and both hot lines registered zero.

- We then went to our in-line surge protector/transfer switch and the service light was not lit.

- We popped the cover on our protector box and found both hot wires had 120 volts going in, but neither line had power going out. We then pressed down on the magnetic switch from the shore power side and it did make a connection. Knowing this we removed the wires from the magnetic switch and bypassed the surge protector and connected the wires directly. (The service lightbulbs were broken and sitting on the bottom of the box.)

- We now had power registering 120 volts for both hot wires coming into our circuit breaker panel. Unfortunately when we started to turn on the individual breakers the 50 amp red hot wire had low voltage -under 100 volts. The black 50 amp hot wire registered a strong 120+ volts with all of the individual circuits on. We also tested all of the black wire circuits and all worked, so we now had full power to half of our rig.

- So now the question became, why do we have low voltage when we turn on individual breakers on the red wire side of the circuit panel? Is there a loose neutral wire somewhere? Did a mouse eat through one of our wires?

- We checked the connections on the GFCI outlet since it was on the red wire side of the panel and all connections were solid.

- We then switched the low voltage breakers on the red side of the panel to the black side and finally everything tested perfect. This was good news as we knew we didn’t blow an air conditioner, microwave, TV, hot water heater, converter, etc...

- So our final test was to run a 50 amp electric cord directly from the pedestal to the circuit panel and finally we had 100% power to everything in the rig.

- We now had the low voltage issue narrowed down to somewhere between our plug, our cord, the power cord reel, or the line from the reel to the surge protector box.

- After we took the metal plate off from the inside of the power cord reel we found the melted red wire and that brings us to our lone question above.

It seems like poor engineering to place potential loose connection fittings on the inside of a power reel that are hard to access. We are happy to finally figure out our power issue and we didn’t end up with an electrical fire!

Our question: Has anyone ordered a package to replace just the electrical connectors on the power cord reel? The reel still works fine and it would be nice to not have to pay $500 for a new reel plus what looks like a very tedious uninstall and reinstall. We did read numerous posts on the Heartland Forum relating to power reel issues and didn’t see an answer to our question.

For those interested in the electrical tests that were performed before we discovered the melted wire, here is the list:

- There was no power in the rig, so we asked our neighbors if they had power, and they all did.

- We checked for any blown circuits and there was none.

- We then used a multimeter to test the power at our outdoor pedestal and both hot lines registered 120 volts.

- We checked the power in our circuit panel on our double 50 amp breaker and both hot lines registered zero.

- We then went to our in-line surge protector/transfer switch and the service light was not lit.

- We popped the cover on our protector box and found both hot wires had 120 volts going in, but neither line had power going out. We then pressed down on the magnetic switch from the shore power side and it did make a connection. Knowing this we removed the wires from the magnetic switch and bypassed the surge protector and connected the wires directly. (The service lightbulbs were broken and sitting on the bottom of the box.)

- We now had power registering 120 volts for both hot wires coming into our circuit breaker panel. Unfortunately when we started to turn on the individual breakers the 50 amp red hot wire had low voltage -under 100 volts. The black 50 amp hot wire registered a strong 120+ volts with all of the individual circuits on. We also tested all of the black wire circuits and all worked, so we now had full power to half of our rig.

- So now the question became, why do we have low voltage when we turn on individual breakers on the red wire side of the circuit panel? Is there a loose neutral wire somewhere? Did a mouse eat through one of our wires?

- We checked the connections on the GFCI outlet since it was on the red wire side of the panel and all connections were solid.

- We then switched the low voltage breakers on the red side of the panel to the black side and finally everything tested perfect. This was good news as we knew we didn’t blow an air conditioner, microwave, TV, hot water heater, converter, etc...

- So our final test was to run a 50 amp electric cord directly from the pedestal to the circuit panel and finally we had 100% power to everything in the rig.

- We now had the low voltage issue narrowed down to somewhere between our plug, our cord, the power cord reel, or the line from the reel to the surge protector box.

- After we took the metal plate off from the inside of the power cord reel we found the melted red wire and that brings us to our lone question above.

It seems like poor engineering to place potential loose connection fittings on the inside of a power reel that are hard to access. We are happy to finally figure out our power issue and we didn’t end up with an electrical fire!