pharmafrog

Active Member

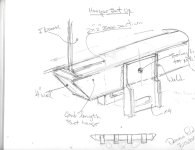

Well, another trip and another broken spring hanger. I had the upgraded supports welded across the frame, but to no avail. the hangar actually sheared and the weld broke on the other side. Pics attached. Now even before this I noticed that my 2nd and 3rd tires are ridiculously close to each other. What gives? I replaced my G-14s with Sailuns. Same size etc.. but dangerously close. Can I just move the axle about an inch back on the spring to give me some breathing room? Any help is appreciated. Just be helpful. Pics also attached of tires.

Note: with the hangar repair it shifted the opposite tire even closer to the middle tire, so close I am sure they rubbed a bit.

Note: with the hangar repair it shifted the opposite tire even closer to the middle tire, so close I am sure they rubbed a bit.