I recently took a trip to Elkhart, IN to pick up my repaired 2012 37 Ultimate. While I was there I was able to go on a factory tour of the Elkridge line and wanted to share that experience with folks who may not be able to make it to Elkhart.

I'm going to apologize as I've not figured out how to properly embed attached images within a posting to provide context (perhaps someone can PM me the directions and I'll fix this post up)

We'll start with the overall process. Like all other assembly lines in Heartland, the units progress from frame to completed unit in a series of stages. The same people work each stage for each coach. On the Elkridge assembly line they build the Elkridge, Sundance, Prowler and apparently the new Oakmount. The employees are not paid hourly. They are paid by number of units. Their full day is 10 units at each stage. It's tight in the assembly line so a delay further down the line can really hold up the start of the line so you can view that as sort of a peer pressure mechanism to keep the assembly line moving to get the 10 units quota done for the day. Each stage has a lead and workers under them. Each stage also has a QC checklist which the lead must sign off on prior to the unit moving to the next stage. According to the Heartland rep. This QC checklist goes all the way to the dealer with the trailer. It was implemented in 2013 so any 2013 and newer trailer should have that in Heartlands files as far as who signed off on what when etc.

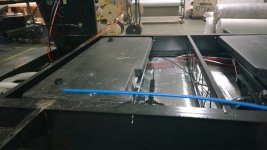

First the frames roll through the entry door on the far side of the assembly plant upside down. The first stage employees attach the axles, wheels, chloroplast under covering and then flip the frame over, set it on a set of trollies for easy pushing down the assembly line floor and then loosely place all the in-frame components into the frame and it's ready for the next stage.

The next stage mounts all of the frame held components securely in place and run all of the electrical, water and other undercarriage items. As soon as this is buttoned up the unit is moved to the next stage.

In this stage the flooring and floor covering are added. They also build up the front floor room creating the storage compartment. Once the flooring is complete it's rolled into the next station.

At this station you start to see the cabinetry being added and some of the room delineating walls being added. Once the room walls and other interior self standing cabinetry and fixtures are added it, Heartland builds all their own cabinetry in house. You'll see a few pictures of stuff waiting to be installed. We pause for a view down the assembly line showing the previous 3 stages. From here it rolls to the next stage (picture or rollers on the landing gear).

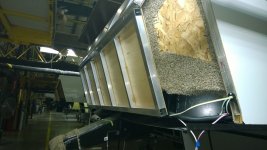

At the next stage they attach the sidewalls. They come from a different shop pre-built all that is remaining is final cut out of the major openings like the slide holes. Those are cut out and sent to the slide making station so that they exactly match the sides of the trailer they came from. there are two pictures in this series. One thing that the representative was proud of was the fact that heartland uses real aluminum and welds in their cornering. It's not plastic or wood filler like some other brands use. Once the walls are attached it's off to the next station.

In this station they add additional internal cabinetry which was waiting on the walls. They also add the roofing at this time. I forgot to capture a picture of this station as it was quite impressive! I was wrapped up in asking questions and not taking pictures. We also start to see lots of interior wiring at this stage taking place.

The next station deals with the external skirting and adds yet more interior work, cabinets, fridge, etc. They also start to finish out the interior bedrooms, bathrooms and kitchen including the front cap structure.

The big difference I saw at the next station was they were focused on the external of the coach. Finishing it off, framing it in and capping/sealing the end cap, adding all the exterior doors and latches. They also completed the front cap placement.

Once the front cap is on they install the slides which were built at a different station in parallel and are sitting on the side waiting to be installed. At this point it's all finish work. The remaining stations focus on all of that finish work. Sealing the unit, adding interior moldings and other things.

The final stage is an actual weigh in of the unit on a certified scale. That weight is posted on the yellow door sticker. Each unit will have it's exact weight on that sticker and not just a generic weight for that floor plan.

From there they move outside and are stored waiting for transport.

I took a picture of one of the QC papers taped to the side of a unit showing where the unit had been damaged while rolling down the assembly line and needed repair. (just an example that heartland does do QC even though it doesn't feel like it sometimes).

Towards the end of the tour I was taking less pictures and blabbing/gawking more at the 38 RSRT floor plan (I think I'm in love!). They just need to fix that rear step issue and I might be trading in for one... maybe.

Anyhow I hope some people find this post interesting in some way to know how the units are built. Sorry that the pictures don't exactly line up!

Thanks for the read!

I'm going to apologize as I've not figured out how to properly embed attached images within a posting to provide context (perhaps someone can PM me the directions and I'll fix this post up)

We'll start with the overall process. Like all other assembly lines in Heartland, the units progress from frame to completed unit in a series of stages. The same people work each stage for each coach. On the Elkridge assembly line they build the Elkridge, Sundance, Prowler and apparently the new Oakmount. The employees are not paid hourly. They are paid by number of units. Their full day is 10 units at each stage. It's tight in the assembly line so a delay further down the line can really hold up the start of the line so you can view that as sort of a peer pressure mechanism to keep the assembly line moving to get the 10 units quota done for the day. Each stage has a lead and workers under them. Each stage also has a QC checklist which the lead must sign off on prior to the unit moving to the next stage. According to the Heartland rep. This QC checklist goes all the way to the dealer with the trailer. It was implemented in 2013 so any 2013 and newer trailer should have that in Heartlands files as far as who signed off on what when etc.

First the frames roll through the entry door on the far side of the assembly plant upside down. The first stage employees attach the axles, wheels, chloroplast under covering and then flip the frame over, set it on a set of trollies for easy pushing down the assembly line floor and then loosely place all the in-frame components into the frame and it's ready for the next stage.

The next stage mounts all of the frame held components securely in place and run all of the electrical, water and other undercarriage items. As soon as this is buttoned up the unit is moved to the next stage.

In this stage the flooring and floor covering are added. They also build up the front floor room creating the storage compartment. Once the flooring is complete it's rolled into the next station.

At this station you start to see the cabinetry being added and some of the room delineating walls being added. Once the room walls and other interior self standing cabinetry and fixtures are added it, Heartland builds all their own cabinetry in house. You'll see a few pictures of stuff waiting to be installed. We pause for a view down the assembly line showing the previous 3 stages. From here it rolls to the next stage (picture or rollers on the landing gear).

At the next stage they attach the sidewalls. They come from a different shop pre-built all that is remaining is final cut out of the major openings like the slide holes. Those are cut out and sent to the slide making station so that they exactly match the sides of the trailer they came from. there are two pictures in this series. One thing that the representative was proud of was the fact that heartland uses real aluminum and welds in their cornering. It's not plastic or wood filler like some other brands use. Once the walls are attached it's off to the next station.

In this station they add additional internal cabinetry which was waiting on the walls. They also add the roofing at this time. I forgot to capture a picture of this station as it was quite impressive! I was wrapped up in asking questions and not taking pictures. We also start to see lots of interior wiring at this stage taking place.

The next station deals with the external skirting and adds yet more interior work, cabinets, fridge, etc. They also start to finish out the interior bedrooms, bathrooms and kitchen including the front cap structure.

The big difference I saw at the next station was they were focused on the external of the coach. Finishing it off, framing it in and capping/sealing the end cap, adding all the exterior doors and latches. They also completed the front cap placement.

Once the front cap is on they install the slides which were built at a different station in parallel and are sitting on the side waiting to be installed. At this point it's all finish work. The remaining stations focus on all of that finish work. Sealing the unit, adding interior moldings and other things.

The final stage is an actual weigh in of the unit on a certified scale. That weight is posted on the yellow door sticker. Each unit will have it's exact weight on that sticker and not just a generic weight for that floor plan.

From there they move outside and are stored waiting for transport.

I took a picture of one of the QC papers taped to the side of a unit showing where the unit had been damaged while rolling down the assembly line and needed repair. (just an example that heartland does do QC even though it doesn't feel like it sometimes).

Towards the end of the tour I was taking less pictures and blabbing/gawking more at the 38 RSRT floor plan (I think I'm in love!). They just need to fix that rear step issue and I might be trading in for one... maybe.

Anyhow I hope some people find this post interesting in some way to know how the units are built. Sorry that the pictures don't exactly line up!

Thanks for the read!

Attachments

-

0011_flooring_frames.jpg266.5 KB · Views: 111

0011_flooring_frames.jpg266.5 KB · Views: 111 -

0010_cabnetry_002.jpg206.1 KB · Views: 91

0010_cabnetry_002.jpg206.1 KB · Views: 91 -

0009_cabnetry_001.jpg196.5 KB · Views: 92

0009_cabnetry_001.jpg196.5 KB · Views: 92 -

0008_flooring_some_cabnetry.jpg262.9 KB · Views: 93

0008_flooring_some_cabnetry.jpg262.9 KB · Views: 93 -

0006_frame_fitted_final.jpg233.5 KB · Views: 91

0006_frame_fitted_final.jpg233.5 KB · Views: 91 -

0005_frame_fitted_items_003.jpg210 KB · Views: 91

0005_frame_fitted_items_003.jpg210 KB · Views: 91 -

0004_frame_fitted_items_002.jpg230.4 KB · Views: 87

0004_frame_fitted_items_002.jpg230.4 KB · Views: 87 -

0003_frame_fitted_items_001.jpg217.9 KB · Views: 87

0003_frame_fitted_items_001.jpg217.9 KB · Views: 87 -

0002_frame_lose_items_001.jpg251.9 KB · Views: 89

0002_frame_lose_items_001.jpg251.9 KB · Views: 89 -

0001_Frame_Tires.jpg197.3 KB · Views: 91

0001_Frame_Tires.jpg197.3 KB · Views: 91 -

0021_finished_rear_cap.jpg121.4 KB · Views: 89

0021_finished_rear_cap.jpg121.4 KB · Views: 89 -

0020_finishing_rear_cap.jpg227.3 KB · Views: 86

0020_finishing_rear_cap.jpg227.3 KB · Views: 86 -

0019_side_skirting.jpg160.9 KB · Views: 80

0019_side_skirting.jpg160.9 KB · Views: 80 -

0018_roof_and_wiring.jpg161 KB · Views: 79

0018_roof_and_wiring.jpg161 KB · Views: 79 -

0017_interiour_wiring.jpg224.6 KB · Views: 78

0017_interiour_wiring.jpg224.6 KB · Views: 78 -

0016_more_interiour.jpg171.2 KB · Views: 74

0016_more_interiour.jpg171.2 KB · Views: 74 -

0015_real_aluminum.jpg208.1 KB · Views: 75

0015_real_aluminum.jpg208.1 KB · Views: 75 -

0014_side_walls_002.jpg184.1 KB · Views: 78

0014_side_walls_002.jpg184.1 KB · Views: 78 -

0013_side_walls_001.jpg201.2 KB · Views: 81

0013_side_walls_001.jpg201.2 KB · Views: 81 -

0012_rolling_chasis.jpg180.3 KB · Views: 80

0012_rolling_chasis.jpg180.3 KB · Views: 80 -

0029_QC.jpg123.1 KB · Views: 83

0029_QC.jpg123.1 KB · Views: 83 -

0028_slides_002.jpg235 KB · Views: 81

0028_slides_002.jpg235 KB · Views: 81 -

0027_slides_001.jpg227.5 KB · Views: 82

0027_slides_001.jpg227.5 KB · Views: 82 -

0026_latches_slides_001.jpg174.3 KB · Views: 78

0026_latches_slides_001.jpg174.3 KB · Views: 78 -

0025_front_cap.jpg171.4 KB · Views: 78

0025_front_cap.jpg171.4 KB · Views: 78 -

0024_front_cap.jpg179.6 KB · Views: 80

0024_front_cap.jpg179.6 KB · Views: 80 -

0023_front_cap_structure.jpg216 KB · Views: 79

0023_front_cap_structure.jpg216 KB · Views: 79 -

0022_doors_added.jpg99.2 KB · Views: 84

0022_doors_added.jpg99.2 KB · Views: 84