Jimsryker

Well-known member

I looked in a bunch of threads and tried to sort via "Secure Battery" and other combinations with no luck, so I will take the lazy route here and just ask. I have just purchased a new AGM 12V battery for my Cyclone 3010 to replace the terrible excuse of a battery that came with my trailer.

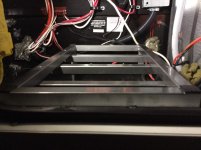

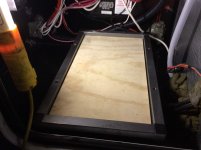

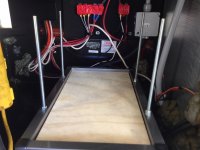

If you know the characteristics of an Absorbed Glass Mat (AGM) battery, I no longer have maintenance concerns or venting issues that I need to work on. I have to basically secure it and hook it up. I plan to put it in the battery compartment up front and in a manner that allows for the planned inverter. It's a behemoth of a battery and it would just about secure itself by virtue of it's weight but we know that's not sufficent. So. I'm sure that other's have crossed this path and I was hoping to hear/see the solutions that others have done themselves or vendors have done to secure their batteries. I won't be using a battery box. Not needed. I am thinking straps?? I weld so I could fab metal brackets?? You never know where the next great idea will come from so have at it guys. And gals...

Thank you in advance!

Jim

If you know the characteristics of an Absorbed Glass Mat (AGM) battery, I no longer have maintenance concerns or venting issues that I need to work on. I have to basically secure it and hook it up. I plan to put it in the battery compartment up front and in a manner that allows for the planned inverter. It's a behemoth of a battery and it would just about secure itself by virtue of it's weight but we know that's not sufficent. So. I'm sure that other's have crossed this path and I was hoping to hear/see the solutions that others have done themselves or vendors have done to secure their batteries. I won't be using a battery box. Not needed. I am thinking straps?? I weld so I could fab metal brackets?? You never know where the next great idea will come from so have at it guys. And gals...

Thank you in advance!

Jim