that can be perfectly normal... and not an issue except to the eye, unless its broke..

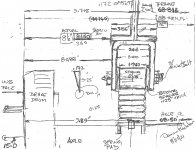

it was installed that way and not a product of road hazard. when onne buys the hangers, they are about a half of an inch wider than the springs, and so one side or the other, or both sides need to bend in when tightened. in that case there, the spring eye was closer to the one side of the hanger than the other, so rather than expecting that little piece of quarter inch material to pull the spring to it, the bolt pulled the hanger to the spring..

the spring suspension systems are very crude, and how it all looks when installed can depend on how exact the installer was in the placement of the hangers, and whether the springs were tight to the axle when the hanger bolts were tightened...

for that hanger shown to fail, it would either have to be broken, which is not likely because its made out of mild steel, or both springs would have to work loose on the axles AND the other side fail too, to allow it to shift sideways enough to collapse...

without a series of events taking place causing it to fail, it wont.... for it to fail on its own without several other issues being present, the spring itself would have to twist between the axle and the hanger to allow the hanger to move from where its at....

its amazing how much abuse and torque trailer suspension takes during rough road travel, and during tight maneuvering in parking lots, driveways and campgrounds... yet very rarely fail in any catastrophic manner.