cj11302000

Member

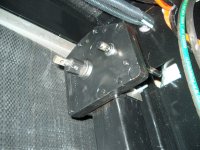

I've seen a lot of talk about landing gear problems and I've posted about them before. Before I buy a new motor or convert to two motors...I'd like to properly lube and inspect the insides of the landing gear. Does anyone have detailed directions or photos on how to do this? I'm not nuts about taking them off the trailer, but will do it if I need to. I have a 2009 Sundance 2997BHS that appears to have the Lippert/Venture landing gear with single motor. There is a black plastic cap on the tops covering the gears. If you look at my previous posts, you will see that I've been having issues with the motor working hard. I can hand crank the gear, but it's pretty difficult...not impossible. Anyway, if anyone has photos or detailed directions or a link with info...that would be great! Thanks!