- Home

- Forums

- HEARTLAND RVs GENERAL AREA

- Exterior Components - For all Heartland brands

- Tires and Wheels (For RV's)

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Wheel nut torque.

- Thread starter Dan50

- Start date

Jim.Allison

Well-known member

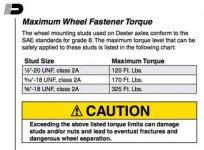

If you have 8 lugs they are 9/16 inch studs, your nut needs to make at least 8 turns and the torque is 135 to 145 ft lbs. I go 140 foot pounds. Here is a link.

http://adaptitusa.com/wheellugnuttorquing.aspx

http://adaptitusa.com/wheellugnuttorquing.aspx

I own a 2012 Elkridge and am wondering that the wheel nut torque should be. I am changing a tire and want to know what I should torque the nuts to. Thanks.

Dan

Jim.Allison

Well-known member

http://www.etrailer.com/question-22600.html

use 140 for 9/16 lugs. clamping force is critical. torque them again after 50 miles. If you don't torque aluminum wheels properly you risk breaking the hub and wheel separation.

use 140 for 9/16 lugs. clamping force is critical. torque them again after 50 miles. If you don't torque aluminum wheels properly you risk breaking the hub and wheel separation.

rxbristol

Well-known member

So, the question is why the difference? Most RV rims with 9/16 lugs are aluminum. I noticed the first time I took off my wheels they had a very high torque. When I torqued them to 120 and later took them off to install the Centramatics, the 120 ft lbs seemed like butter compared to the original torque value.

Jim, I'm counting on your extensive research here .

.

Jim, I'm counting on your extensive research here

Jim.Allison

Well-known member

If there is any doubt in the accuracy or torque requirements for a 9/16 lug, consult your owners manual for specifics to your vehicle. Do not use oil or anti seize on the threads pay particular attention to the torque sequence, retorque after 50 miles to verify the torque and to compensate for any irregularity in the hub caused by repositioning the wheel this is critical on a new wheel as well as a used wheel. Without specifics from an owners manual, 140 lbs would be your standard torque specification for a 9/16 lug. If you don't have the owners manual, then you should look at the wheel manufacturers specifications for the torque data, absent all other data, use the standard torque spec for a 9/16 lug which is 135 to 145 ft lbs of torque, retorque after 50 miles using proper sequencing, in order to achieve proper clamping force. I use 140 because it splits the difference.

The owners manual that came with my new BH says 120.

Jim.Allison

Well-known member

Thanks, but I just went through all of this when I bought HiSpec rims. I usually verify claims made by manufacturers before I buy, I did discover this subject during that research. I also know that the ultimate source is the owners manual, or wheel manufacturer, then lastly the standard torque specs, in that order. Dexter Axle will not give you a torque spec and they will refer you to the owners manual, if you change wheels your owners manual is not accurate anymore, but your wheel manufacturer specs are. Absent those figures then the standard applies. Dexters lugs are designed to take the values on the standard torque rating for lugs.

Remember when they were wiring houses with aluminum wire? They had a terrible time with burning down houses, they determined it to be the aluminum wire being used because copper was so expensive then. This was caused by a physical property of aluminum. Aluminum tends to give away to pressure, in the case of the wiring the lugs that held the wire were of a compressive nature and the wire would be tight when the electrician installed the wire but would give away to the pressure resulting in a loose connection and subsequent arc which caused the fires. Since then they developed a lug and a paste to secure aluminum wire. This has cured the problem.

In the case of the aluminum wheel, the hub does the same thing to an extent (wheel alloy is harder than wire alloy) so when you torque the wheel the manufacturer knows through engineering where that initial torque spec will decrease to in the application. So torque, then retorque after 50 and your wheels are set. they will give away to the pressure to a known value. With the wheel alloy there is very little difference, but a very small amount will loosen the lug and give you the feeling you experienced. This is why HiSpec wheels with steel lug inserts are worth the money for a rig if you intend to drag it all over the country. You torque them once and do not torque again except to verify. BTW never torque a hot hub.

I always use a torque wrench so that I can determine what the wheel is torqued to when I take it off, then that way I do not have to feel it, I measured it. If your torque value is 140 such as in my case, then I set my wrench to 135. If it breaks after 135, then we are good, but if it does not break soon after 135, i readjust the torque wrench to 140 and do it again, do this progressively until you get a break, in this manner you will know where they were. Remember they will not always break the same coming off so take it with a grain of salt. You should also remember that if you originally torqued a lug, and the torque decreases significantly for that lug then you need to change the lug because it is stretching. you will find this out at the 50 mile check. Dont panic retighten it, mark it and try to re torque it later. If it keeps giving away you need to find out why.

It is note worthy that the compression of the aluminum hub is probably not detectable by a common torque wrench. So if you torque to 140 it should stay at 140. Always use the same torque wrench. if one torque wrench is off by -2.5 lbs and another is off by +2.5 lbs then that is a significant 5 lbs. So if you are given a range of 135 to 145 and you desire to torque to 145 you could be off quite a bit especially if you use two different torque wrenches. I always split the difference in a range anyway.

This is conjecture based on some research, and my interpretation of it, take it to the extent that it makes sense to you. I'm certainly not an engineer, but I am a good wrench. I have my share of screwups and misconceptions. But I promise if you torque a 9/16 lug to 140 and it twist off then it is a bad lug.

Remember when they were wiring houses with aluminum wire? They had a terrible time with burning down houses, they determined it to be the aluminum wire being used because copper was so expensive then. This was caused by a physical property of aluminum. Aluminum tends to give away to pressure, in the case of the wiring the lugs that held the wire were of a compressive nature and the wire would be tight when the electrician installed the wire but would give away to the pressure resulting in a loose connection and subsequent arc which caused the fires. Since then they developed a lug and a paste to secure aluminum wire. This has cured the problem.

In the case of the aluminum wheel, the hub does the same thing to an extent (wheel alloy is harder than wire alloy) so when you torque the wheel the manufacturer knows through engineering where that initial torque spec will decrease to in the application. So torque, then retorque after 50 and your wheels are set. they will give away to the pressure to a known value. With the wheel alloy there is very little difference, but a very small amount will loosen the lug and give you the feeling you experienced. This is why HiSpec wheels with steel lug inserts are worth the money for a rig if you intend to drag it all over the country. You torque them once and do not torque again except to verify. BTW never torque a hot hub.

I always use a torque wrench so that I can determine what the wheel is torqued to when I take it off, then that way I do not have to feel it, I measured it. If your torque value is 140 such as in my case, then I set my wrench to 135. If it breaks after 135, then we are good, but if it does not break soon after 135, i readjust the torque wrench to 140 and do it again, do this progressively until you get a break, in this manner you will know where they were. Remember they will not always break the same coming off so take it with a grain of salt. You should also remember that if you originally torqued a lug, and the torque decreases significantly for that lug then you need to change the lug because it is stretching. you will find this out at the 50 mile check. Dont panic retighten it, mark it and try to re torque it later. If it keeps giving away you need to find out why.

It is note worthy that the compression of the aluminum hub is probably not detectable by a common torque wrench. So if you torque to 140 it should stay at 140. Always use the same torque wrench. if one torque wrench is off by -2.5 lbs and another is off by +2.5 lbs then that is a significant 5 lbs. So if you are given a range of 135 to 145 and you desire to torque to 145 you could be off quite a bit especially if you use two different torque wrenches. I always split the difference in a range anyway.

This is conjecture based on some research, and my interpretation of it, take it to the extent that it makes sense to you. I'm certainly not an engineer, but I am a good wrench. I have my share of screwups and misconceptions. But I promise if you torque a 9/16 lug to 140 and it twist off then it is a bad lug.

So, the question is why the difference? Most RV rims with 9/16 lugs are aluminum. I noticed the first time I took off my wheels they had a very high torque. When I torqued them to 120 and later took them off to install the Centramatics, the 120 ft lbs seemed like butter compared to the original torque value.

Jim, I'm counting on your extensive research here.

rxbristol

Well-known member

Thanks, Jim...lots of good stuff. I knew I could count on your extensive research skills.

Thanks, but I just went through all of this when I bought HiSpec rims. I usually verify claims made by manufacturers before I buy, I did discover this subject during that research. I also know that the ultimate source is the owners manual, or wheel manufacturer, then lastly the standard torque specs, in that order. Dexter Axle will not give you a torque spec and they will refer you to the owners manual, if you change wheels your owners manual is not accurate anymore, but your wheel manufacturer specs are. Absent those figures then the standard applies. Dexters lugs are designed to take the values on the standard torque rating for lugs.

Remember when they were wiring houses with aluminum wire? They had a terrible time with burning down houses, they determined it to be the aluminum wire being used because copper was so expensive then. This was caused by a physical property of aluminum. Aluminum tends to give away to pressure, in the case of the wiring the lugs that held the wire were of a compressive nature and the wire would be tight when the electrician installed the wire but would give away to the pressure resulting in a loose connection and subsequent arc which caused the fires. Since then they developed a lug and a paste to secure aluminum wire. This has cured the problem.

In the case of the aluminum wheel, the hub does the same thing to an extent (wheel alloy is harder than wire alloy) so when you torque the wheel the manufacturer knows through engineering where that initial torque spec will decrease to in the application. So torque, then retorque after 50 and your wheels are set. they will give away to the pressure to a known value. With the wheel alloy there is very little difference, but a very small amount will loosen the lug and give you the feeling you experienced. This is why HiSpec wheels with steel lug inserts are worth the money for a rig if you intend to drag it all over the country. You torque them once and do not torque again except to verify. BTW never torque a hot hub.

I always use a torque wrench so that I can determine what the wheel is torqued to when I take it off, then that way I do not have to feel it, I measured it. If your torque value is 140 such as in my case, then I set my wrench to 135. If it breaks after 135, then we are good, but if it does not break soon after 135, i readjust the torque wrench to 140 and do it again, do this progressively until you get a break, in this manner you will know where they were. Remember they will not always break the same coming off so take it with a grain of salt. You should also remember that if you originally torqued a lug, and the torque decreases significantly for that lug then you need to change the lug because it is stretching. you will find this out at the 50 mile check. Dont panic retighten it, mark it and try to re torque it later. If it keeps giving away you need to find out why.

It is note worthy that the compression of the aluminum hub is probably not detectable by a common torque wrench. So if you torque to 140 it should stay at 140. Always use the same torque wrench. if one torque wrench is off by -2.5 lbs and another is off by +2.5 lbs then that is a significant 5 lbs. So if you are given a range of 135 to 145 and you desire to torque to 145 you could be off quite a bit especially if you use two different torque wrenches. I always split the difference in a range anyway.

This is conjecture based on some research, and my interpretation of it, take it to the extent that it makes sense to you. I'm certainly not an engineer, but I am a good wrench. I have my share of screwups and misconceptions. But I promise if you torque a 9/16 lug to 140 and it twist off then it is a bad lug.

Jim.Allison

Well-known member

If your 9/16 lugs strip at 140 foot lbs you need to replace them anyway.......Its not about the lugs its about clamping force. Dexter Axle uses grade 8 lugs good to 170 ft lbs torque. Although torque ranges vary widely, Aluminum wheel manufacturers say 120 to 140, heartland says 120, other trailer wheel folks identify 135 to 145. My owners manual says 120 which in my opinion is for a 1/2 in lug, not a 9/16 in lug. So the upshot is 120 minimum published from Heartland, 145 max from from aluminum wheel charts. And you can rest assured that 145 is not going to break or strip a dexter 9/16 lug. Its 140 for me on a 15,500 lb rig with 16 inch 3500 lb tires. If its 120 who the heck needs a torque wrench, I can guess at that.

Who pays for broken or stripped studs when people start torquing to 145 when heartland recommendation is 120?

And the quality of OEM lug nuts needs to be taking into consideration. Lug nuts with chrome caps are not up to the same quality of solid lug nuts.

Jim.Allison

Well-known member

rxbristol

Well-known member

Jim.Allison

Well-known member

Do not torque that wheel to 170 lbs........LOL "Porthole" will be laughing at us and telling us "I told you so" Then he will want me to pay for the twisted off lug bolt. Stay with the 135 to 145.

Awesome...thanks.

Jim.Allison

Well-known member

I will try it next time. Of course I was using satire to illustrate a point. If I manage to actually do it can I claim the beer on the honor system?

I won't be laughing - but I would bet you a case of domestic beer that you can't guess even once 120 ft lbs on any of the lugs on all four wheels.

porthole

Retired

If I manage to actually do it can I claim the beer on the honor system?

Absolutely

Thanks Jim! I just removed my 16" wheels w/GY614s after three years and 25,000 miles. I'm replacing them w/17.5 wheels and GY114s. I found quite a range of torques when removing, probably from a service tech using an air wrench when reinstalling wheels after bearing repack last fall. I also found a very noisy bearing on right front and slightly noisy bearing on left front. Front axle likely carries more than rear. I'm replacing all bearings and seals w/Timkins before installing new wheels.

rxbristol

Well-known member

Thanks Jim! I just removed my 16" wheels w/GY614s after three years and 25,000 miles. I'm replacing them w/17.5 wheels and GY114s. I found quite a range of torques when removing, probably from a service tech using an air wrench when reinstalling wheels after bearing repack last fall. I also found a very noisy bearing on right front and slightly noisy bearing on left front. Front axle likely carries more than rear. I'm replacing all bearings and seals w/Timkins before installing new wheels.

Are you going to replace your races too so they match up to your new bearings?

Similar threads

- Replies

- 7

- Views

- 889

- Replies

- 2

- Views

- 206

- Replies

- 7

- Views

- 843

- Replies

- 3

- Views

- 143