With the electric stabilizer jacks- they run at the same time rather than independently. The ground wasn't level so I used the orange blocks under the feet to get them as even as I could. Still one hit first and the other was still about 1/2" off the block. I continued lowering hoping for the best. They seemed to do fine, but I worry about over-stressing one or popping a gear. Any thoughts or suggestions? I could be worrying too much.

I've often worried about that as well . . .

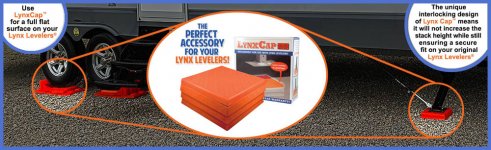

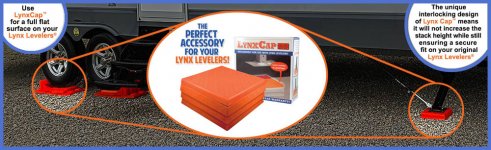

I see you are using the orange blocks (Lynx Leveling Blocks).

I have those as well and I found these in the parts store at our dealership (Four Seasons RV in Loveland, although I'll bet they have them at their Wheatridge store):

http://trilynx.com/lynx-cap/

http://trilynx.com/lynx-cap/

Camping World sells the blocks . . . but not the caps.

I bought four of them and love them (I am going to buy another set soon)!

They are about half as thick as the blocks, so you can fill that extra gap when one jack hits first.

The main reason I wanted them is because I wanted a flat surface to have the tires on while the trailer is parked all winter in our side yard.

- - - Updated - - -

It is normal for one pad to hit the ground then the other will follow.

Once they are both grounded there is, or should be, equal pressure at that time.

True . . . but could this be a possible cause for the frame flex issues we read about a lot here?

.

.